EB Series Electric Stretch Blow Moulding Machines

Brief Introduction

EB Series is the latest linear designed Electric Stretch Blow Moulding Machine developed after years of R&D by Mega. Thanks to the variable pitch unit, synchronized heating system and high speed clamping design, the 10 cavity machine makes 0.5L water bottles at 16,000BPH. The bottle production cost for the end of user by using the Electric stretch blow moulding machines is much less than traditional machine and rotary blow moulding machine.

Overview

* Precise controller

Large Touch Screen graphics interface with access to and storage of all the parameters for the control of the machine and heating and blowing processes. Self diagnostics and remote control with Mega customer support are also provided in the latest version.

* Preform loading system

Thanks to a continuous preform loading system which is the same one used in Mega’s rotary technology , high speed preform loading requirements are met and are easy to change at the feeding wheel for different sized neck finishes.

* Preform pre-heater

Super small mandrel pitch makes the EB series consume less power. This is the key to reducing bottle production costs and increasing profit for the bottle producer. Efficient oven cooling and cross ventilation systems prevent crystallization, even for very thick perform walls.

* Variable pitch system

A Servo motor driven variable pitch system synchronizes with the preform mandrels. This system reduces preform transfer times and ensures reliable variable pitch changing. Due to the wider preform distance after changing pitch, the machine is able to handle different size bottles.

* Toggle designed clamping system

EB series electric stretch blow moulding machine adopts a uniquely designed clamping system with double sided pneumatic compensation to ensure the mold remains tightly closed during high pressure blowing and guarantees a consistent quality parting line on the bottle surface. No hydraulics are used for clamping the part, this helps the blow mold from wearing out over time and provides easy maintenance.

Options

* PID system for heating zone

An Infrared thermometer detects the temperature of the preforms and automatically adjusts the temperature of the oven to the correct level. It avoids the influence of the temperature difference between day time and night time. Also, the system can have an additional lamp alarm unit, It soundswhen it detects any broken or aging lamps.

* Air Recovery system

We know most of the production cost comes from two factors, blowing the bottles and reheating the performs . In order to reduce the production cost for the bottler producer, Mega has introduced an Air recovery system. This system recovers up to 30% of exhausted High pressure air.

* Air cooling system

Thanks to our GM Cai Yuansen , we have developed an air cooling system for hot fill PET bottles, after high pressure blowing, air cooling is introduced. This reduces the level of PET residual stress, and increases the rate of PET crystallization. After the air cooling process, the PET bottle can stand hot filling without deformation.

Features

* Preform feeding system

1. Linear unscrambler is fixed on the top of the machine for saving space.

2. Preform loading is continuous with high speed (the same as our rotary machine )

3. quick change feeding wheel design.

* Advance heating system

1. Unique venting design for both lamps and preforms .

2. Cooling ramp to protect the neck of the preforms .

3. Closed loop system for the heating system

* Transfer of performs

1. Servo driven variable pitch system.

2. Easy design for the preform grips providing less change over time

* Clamping system

1. Double side compensation.

2. Toggle clamp with self-lubricating graphite bearings.

3. Synchronized horizontal and vertical movement

* Automation system

1. Top Brand electronic components.

2. Large touch screen that saves up to 30 sets of data.

3. Remote control unit with MEGA customer support service.

Bottle Samples

PET bottles produced by EB series machine:

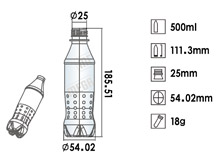

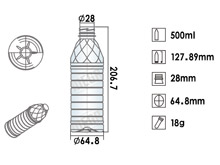

CSD-500ml

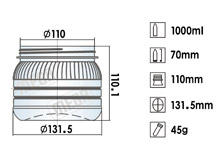

Jar-1L

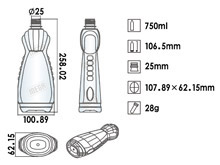

Detergen-750ml

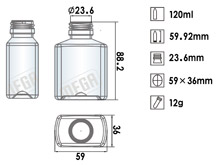

Pharmacal-bottle120

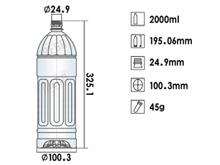

Hot-fill-2L

Water-500ml

Specification

| General Information | EB6 | EB8 | EB10 |

|---|---|---|---|

| Clamping Force | 54T | 84T | 106T |

| Clamping Stroke | 130mm | 130mm | 130mm |

| Max. Stretching Stroke | 370mm | 370mm | 370mm |

| Bottom Moving Stroke | 10-70mm | 10-70mm | 10-70mm |

| Number of Cavities | 6 Cavity | 8 Cavity | 10 Cavity |

| Theoretical Output | 10000 BPH | 12800 BPH | 15500 BPH |

| Mould Thickness | 320mm | 260mm | 260mm |

| Electrical System | |||

|---|---|---|---|

| Voltage Standard | 380v/3PH/50Hz | or special order | — |

| Number of Heating Zone | 6 Sections | 12 Sections | 14 Sections |

| Total Power (Full Loaded) | 85KW | 165 KW | 185KW |

| Container | |||

|---|---|---|---|

| Max. container Volume | 2.5L | 2.5L | 2.5L |

| Neck Diameter Range | 32mm | 32mm | 32mm |

| Max. Container Diameter | 100mm | 100mm | 100mm |

| Dimension & Weight(L*W*H) | |||

|---|---|---|---|

| Blow molding machine | 4X2.1X1.9m | 7X2.1X2m | 7.8X2.1X2m |

| Preform Autoloader | 2.2X1.5X2.5m | 2.2X1.8X2.5m | 2.5X2X3m |

| Net Weight | 7.0Ton | 8.5Ton | 9.8Ton |

| General Information | EBL2 | EBL3 | EBL4 |

|---|---|---|---|

| Clamping Force | 100T | 65T | 90T |

| Clamping Stroke | 300mm | 220mm | 220mm |

| Max. Stretching Stroke | 630mm | 400mm | 400mm |

| Bottom Moving Stroke | 80mm | 30-70mm | 30-70mm |

| Number of Cavities | 2 Cavity | 3 Cavity | 4 Cavity |

| Theoretical Output | 20L recyclable: 500BPH | 2900 BPH | 3500 BPH |

| 20L one-time: 1000BPH | |||

| Mould Thickness | 420mm | 350mm | 350mm |

| Electrical System | |||

|---|---|---|---|

| Voltage Standard | 380v/3PH/50Hz | or special order | — |

| Number of Heating Zone | 8 Sections | 8 Sections | 10 Sections |

| Total Power (Full Loaded) | 203.5 KW | 120 KW | 145 KW |

| Container | |||

|---|---|---|---|

| Max. container Volume | 20L | 5L | 5L |

| Neck Diameter Range | 65mm | 46mm | 46mm |

| Max. Container Diameter | 250mm | 180mm | 180mm |

| Dimension & Weight(L*W*H) | |||

|---|---|---|---|

| Blow molding machine | 5×2.26×1.9m | 4.8X2.2X2m | 6.2X2.2X2m |

| Preform Autoloader | 1.5×1.8×2.3m | 2.2X1.8X2.5m | 2.2X1.8X2.5m |

| Net Weight | 11Ton | 7.5Ton | 8.5 Ton |

Remark: EBL is suitable for large size 5L container, EB is designed for the bottles up to 2.5L

Mega Machinery, the Professional electric stretch blow moulding machine supplier in China.

Note: PET stretch blow molding machine is also known as Reheat stretch blow molding machines, Stretch blow molding machines and PET blow molding machine.